Is a liquid-filled pressure gauge right for me?

Learn how to troubleshoot common issues with liquid-filled pressure gauges with SJ Gauge's expert guidance in 5 minutes!

Contents

- 01When to use a liquid-filled pressure gauge?

- 02What should you do if the pressure gauge leaks liquid?

- 03How to choose which liquid?

- 04Can the gauge be used if the liquid is not full?

- 05Why does the liquid turn yellow? Can it still be used when this happens?

- 06Why can't the pressure gauge return to zero?

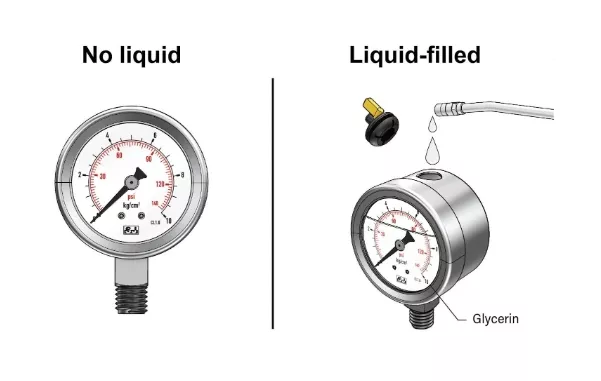

1. When to use a liquid-filled pressure gauge?

Liquid-filled pressure gauges, also known as shock-resistant pressure gauges, are injected with liquid between the pressure gauge case and the components. This lubricates the components so that they are not easily worn, extending the life of the pressure gauge. It can reduce negative effects on the pointer when the pressure change amplitude is large, reduce fluctuations and reduce the impact of vibration on the reading. A liquid-filled pressure gauge is suitable for the use of machinery with large vibration, such as: plastic injection molding machines, compressor machines, and other types of machinery.

2. What should you do if the pressure gauge leaks liquid?

Leakage is uncommon under normal use, but there are several things that may cause leakage.

Liquid leaking from the plug:

- The oil plug may not be tightened well, because the plug is not completely sealed. In this case, just reinstall the plug and put the pressure gauge on the paper to test whether the liquid is still leaking.

- The pressure gauge oil plug was damaged (loss of elasticity, damage, etc.), resulting in liquid leakage. You need to replace the damaged plug and install a new one.

- For more severe factors (collisions, heavy damage, etc.), you may have to send it back to the manufacturer for replacement or repair.

Liquid leaking from the case:

- The case was not installed properly and needs to be returned to the manufacturer for replacement or repair.

- The pressure gauge is affected by external factors, resulting in damage to the pressure gauge, recommended replacement.

- There are defects in the pressure gauge itself, requiring a manufacturer to repair it.

3. How to choose which liquid?

The liquid is mainly divided into glycerol and silicone oil, although these two can be used in the pressure gauge, but the effect is different. Both of these liquids have a very good seismic effect, but the price of glycerin is relatively cheaper, and popular in the market. Silicone oil is more expensive, but silicone is more resistant to low temperatures than glycerol. If the ambient temperature is below - 20 °C, glycerol will crystallize, but silicone can still function.

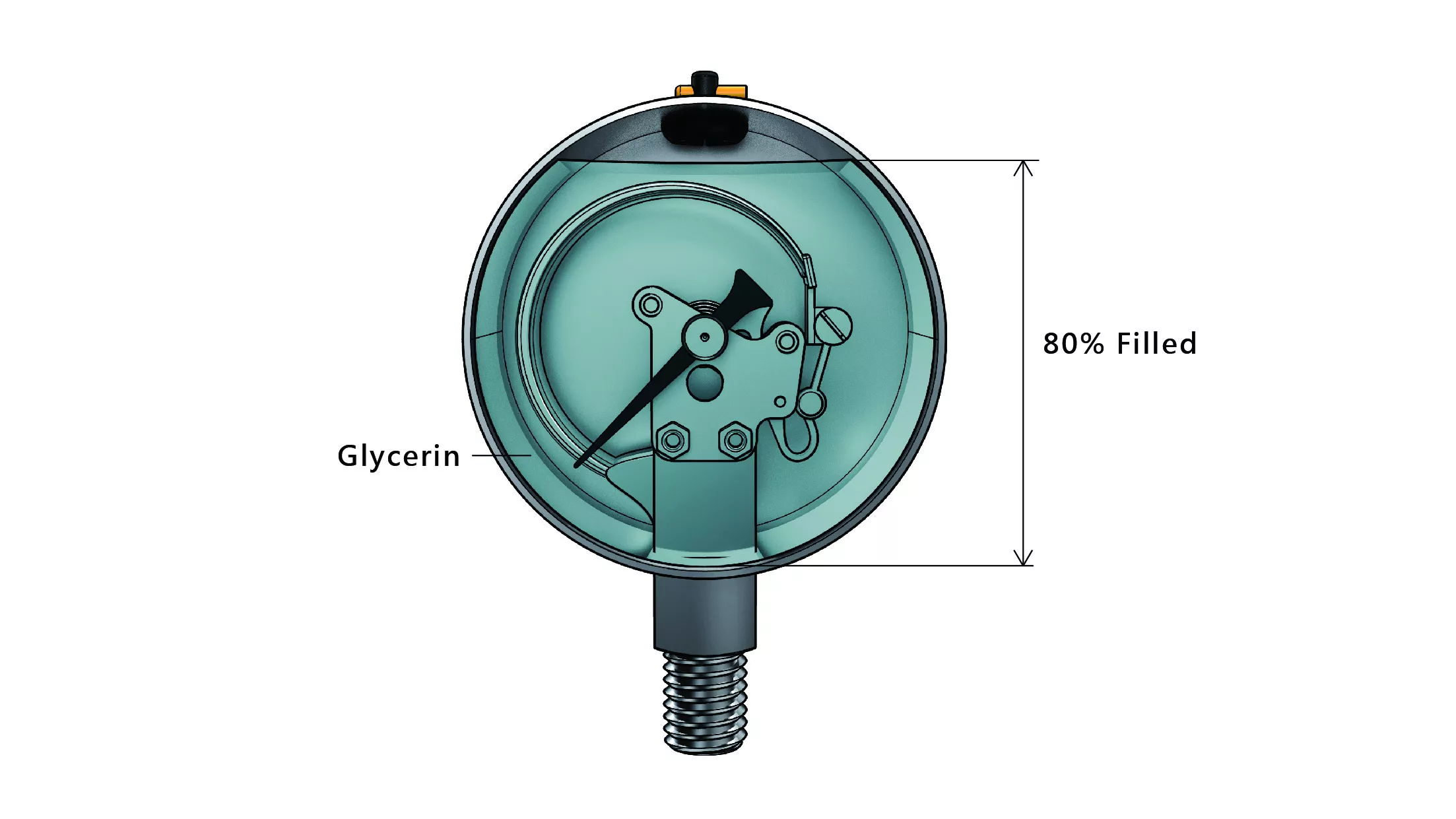

4. Can the gauge be used if the liquid is not full?

Yes, as long as the liquid is about 80% full, and the components are completely covered and protected.

5. Why does the liquid turn yellow? Can it still be used when this happens?

It is not recommended to use a liquid pressure gauge if the liquid has turned yellow. This can lead to difficulties and even obscure reading.

The liquid may turn yellow due to the following reasons:

- Prolonged exposure to the sun

- Use at high temperatures

- A problem with the liquid itself

- Unwashed welding of the bourdon tube

- The dial and pointer have faded

When the liquid turns yellow, you can just pour out the spoiled liquid and use it as a general pressure gauge, or inject new liquid into it.

6. Why can't the pressure gauge return to zero?

The pointer can't return to zero mainly due to the following reasons:

- The pressure is unbalanced inside and outside of the pressure gauge, causing the pointer to become non-zero. When using a liquid-filled pressure gauge, open the oil plug, let the internal and external atmospheric pressure balance. After the gauge returns to zero, close the oil plug.

- The pressure gauge is damaged, resulting in damage to the part.

- The operating environment temperature is too high, resulting in deformation of the Bourdon tube. This can prevent the pointer from returning to zero and the pressure to be inaccurate.

We hope that after this short article, everyone has more knowledge of liquid-filled pressure gauges! Click below to read more and learn more about pressure gauges!